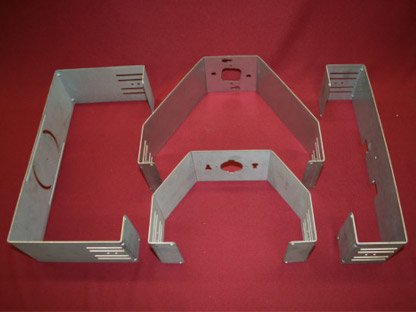

As a customer-centric provider of precision blanking and forming products, we deliver superior customer service, and value added products. The lighting yoke brackets shown here exemplify these services. Because we built a positive relationship with this customer we were able to review in-depth the project requirements to develop a process that would deliver the greatest cost savings possible.

In this project, our analysis resulted in the determination that aspects of the dies that would be used were very similar. This allowed us to use the same tooling for many of the angles, saving the customer a great deal in tooling cost. It also allowed for savings in production cost due to less tool change overs. We are producing 22 parts using the same interchangeable tooling from blanking and forming.

The finished brackets were blanked and formed from .056" thick, galvanized, cold rolled steel, on our 110 STAMTEC Gap Press, which delivered tolerances of ±.005" on the dimensions, and ±2° on the angles. After forming, parts are inspected visually and dimensionally before deburring. We currently stock these parts for this customer shipping a low of 240 and as high as 20,000 yearly.